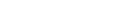

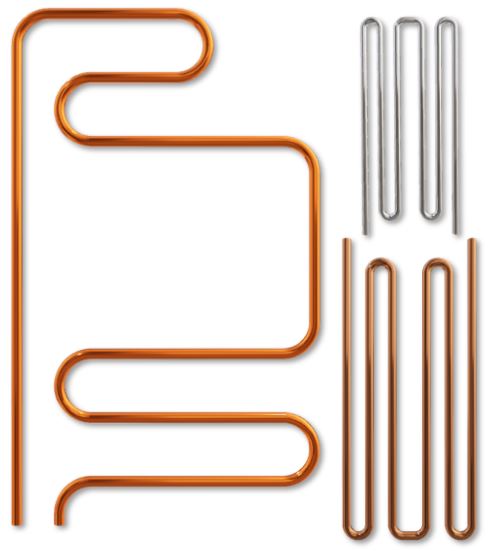

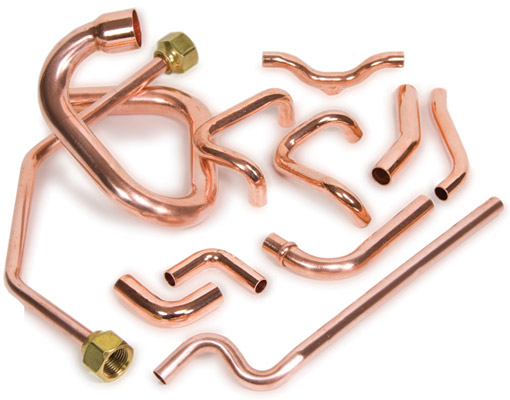

Tube fabrication and tube bending are a few of ETI’s core competencies. We pride ourselves in being one of the most recognized companies for tube bending and fabrication in the industry. Feel confident that your designs are being produced on one of our many advanced CNC tube benders by our highly skilled operators. Not only do we have an impressive line of CNC tube benders we also house many other well-known brands of tube forming machines all specially designed to meet the demands of our evolving markets. Rest assured that ETI will ensure that our tube bending and tube fabrication will provide your company; with improved Quality, better repeatability, shortened lead times, timely delivery and improve your internal efficiencies through fit and function.

ETI machines and maintains all of our own tooling, to eliminate the bottleneck so often seen by many of our competitors. Internally we have the capabilities to produce custom tooling designed in our specialized tooling department, housing an extensive line of specialized equipment and skilled staff. This allows our customers more flexibility in their tube bending designs. For you, our customer, this means that tooling costs are drastically reduced with improved lead times and ETI ensures that our high quality standards are maintained through our world class ISO9001:2015 Quality System.

Let our highly skilled staff work with your team during your tube bending design phase, or if you’re looking for cost savings in your current designs. Take advantage of our hundreds of years’ experience in tube bending and tube fabrication. We’ve helped many companies, just like yours, improve on their product costs and/or overall costs.

ETI specializes in short-to-medium run parts that require a high degree of difficulty to produce. We engineer and produce continuous tubular designs where others would require brazing, joints or connectors. This ability greatly reduces stress and failure points, increases reliability and reduces overall costs by eliminating secondary operations (less labor and material). Utilizing dedicated tooling departments at all our three locations, we use innovative methods to rapidly produce prototypes and support you in new product design and testing.

Contact us in your design phase and let us help you produce a great part!

Copyright © 2024 Elkhart Tri-Went Industrial. Designed By Net-Noggin